Six Sigma - CPK, Sigma, DPPM

One of the most useful and important ideas I've learned from work is Six Sigma. I'm surprised they don't teach this in school more since it is so useful in the industry. Basically, the idea is that you want to design your process to have sufficient margin so that the yield is guaranteed to be high.

Basic terminology - terms that people assumed I know at work

DPPM - defective parts per million

Sigma - the sigma in six sigma just refers to the standard deviation

So how good is good enough?

Here is what we normally use for consumer electronics:

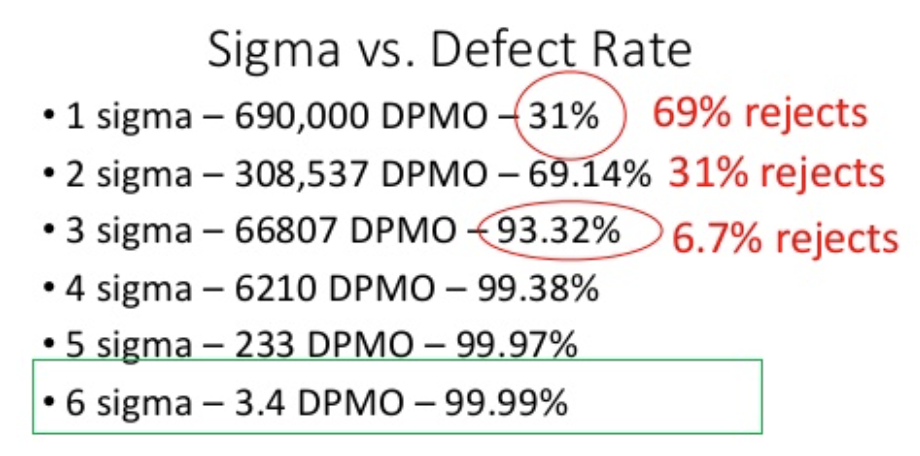

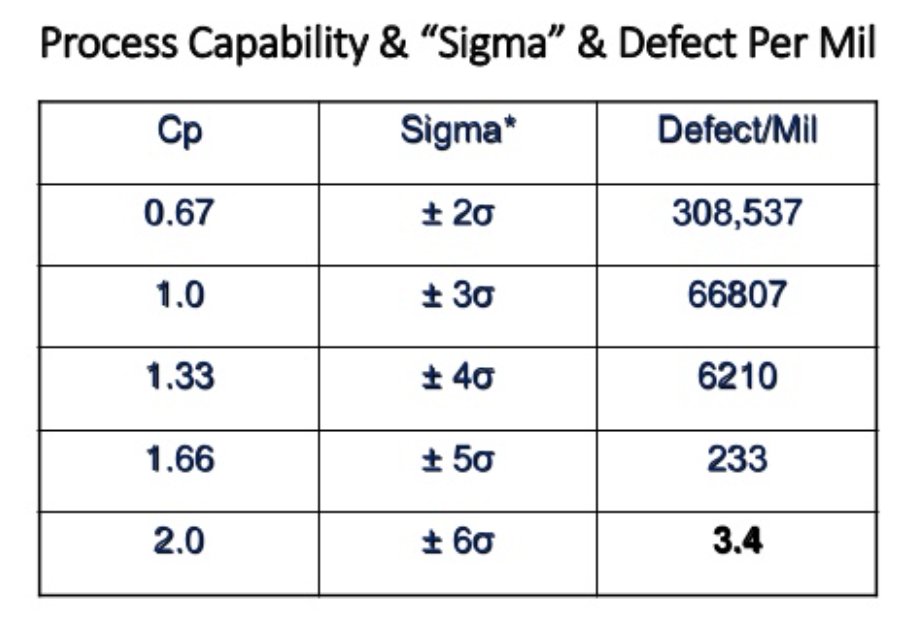

Good CPK = 1.33 (4σ), this means ~6210 DPPM, we use this, but you don't want to be here.

Better CPK = 1.67 (5σ), this means 233 DPPM.

When you read this below table, 4 sigmas means 4 sigma on each side! Meaning the width is actually 8 sigmas.

CPK = 1.33 is considered "capable".

So for example, let's say you have a distribution that is centered at 20 with an stdev = 3, then ±4σ is ±12.

- The distribution LCL (lower control limit) = 20 - 12 = 8

- The UCL (upper control limit) = 20 + 12 = 32

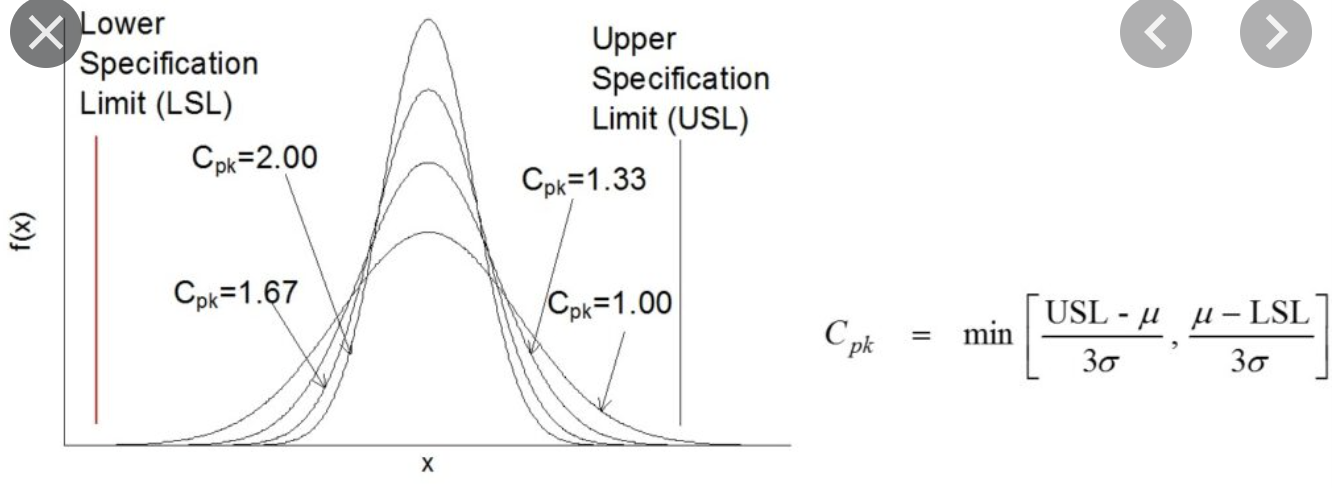

Formula for CPK

Note below is the formula for CPK.

Notice the denominator is 3σ.

Using some numbers as example:

If the mean is 50, σ is 5, USL is 80, LSL is 20:

C_pk = min (30/15, 30/15) = 2

If USL is 65, LSL is 35:

C_pk = min (15/15, 15/15) = 1

C_pk = 1 if spec limit is 3σ from the mean